Insert Molds

What is an Insert Mold?

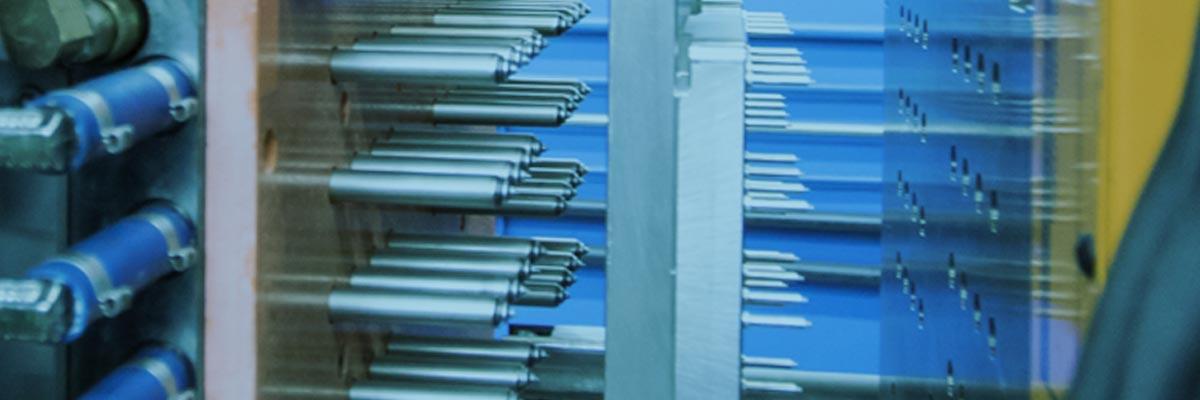

2-cavity mouthpiece moldInsert molds bring multiple materials and components together to create a single product. The process can use engineering plastics or rubber with metallic materials, which provide strength and conductivity.

2-cavity mouthpiece moldInsert molds bring multiple materials and components together to create a single product. The process can use engineering plastics or rubber with metallic materials, which provide strength and conductivity.

Inserts can be magnets, screws, pins, clips, rivets, etc., from materials such as steel, stainless steel, aluminum, titanium, plastic and silicone. The insert is placed in the mold, either by hand or automation, before the material is injected into the mold. As material flows into undercut features in the insert, the insert is anchored more securely than if it were assembled. Vertical molding keeps the insert in position during the molding process.

Our Insert Mold Capabilities

M.R. Mold has full capabilities to build and test insert molds. The insert must be able to withstand the injection molding process without damage. It is crucial that the insert match the precise design dimensions. If the insert varies in any way, molding a perfect part will be impossible. With our vertical and horizontal machines, we can validate your mold in a vertical press.

Below is an example product, where we overloaded two inserts simultaneously.